|

|

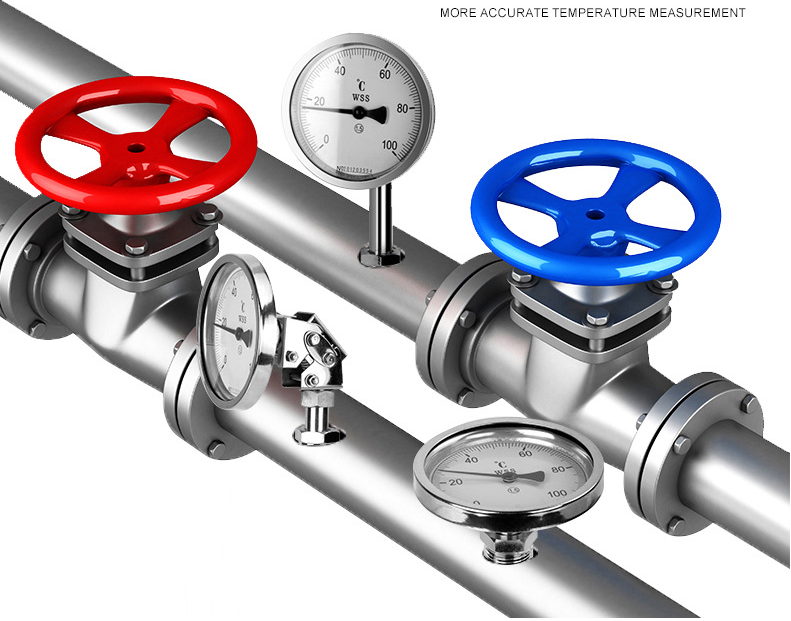

Common types and installation precautions of bimetal thermometerTime:2023-03-14

The bimetal thermometer is based on the bimetal sheet winding into a circular bending shape. When one end is heated and expanded, it drives the pointer to rotate, and the working instrument displays the temperature value of the thermoelectric potential. Bimetal thermometer is a field temperature detection instrument used to measure medium and low temperature. It can directly measure the temperature of liquid, steam and gas medium in the range of - 80 ℃~+500 ℃ in various production processes. Main technical parameters of bimetal thermometer 1. Product executive standard choosing. 2. Nominal diameter of dial: 60100150; 3. Accuracy class: (1.0), 1.5; 4. Thermal response time: ≤ 40s; 5. Protection grade: IP55; 6. Angle adjustment error; 7. The angle adjustment error shall not exceed 1.0% of its range; 8. Return error: the return error of the thermometer shall not be greater than the absolute value of the basic error limit; 9. Repeatability: the repeatability limit range of the thermometer shall not be greater than 1/2 of the absolute value of the basic error limit; 10. Temperature measurement range

Precautions for installation of bimetal thermometer For the installation of bimetallic thermometer, attention should be paid to accurate, safe and reliable temperature measurement, convenient maintenance, and not affect the equipment operation and production. At the same time, pay attention to the following points when selecting the installation position and insertion depth of the thermal resistor: (1) In order to ensure sufficient heat exchange between the measuring end of the thermal resistance and the measured medium, the location of the measuring point should be reasonably selected, and the installation of the thermal resistance near the dead angle of the valve, elbow, elbow, etc. should be avoided as far as possible. Piping and equipment. (2) Thermistors with protective sleeves have heat transfer and heat dissipation losses. In order to reduce measurement error, thermocouple and thermal resistance shall have sufficient insertion depth: A. Thermal resistance used to measure the fluid temperature at the center of the pipeline. Generally, the measuring end shall be inserted into the center of the pipe (vertical installation or inclined installation). If the pipe diameter of the measured fluid is 200 mm, the insertion depth of the thermal resistor should be 100 mm; B. Used for temperature measurement of high temperature, high pressure and high speed fluids (such as main steam temperature). In order to reduce the resistance of the protective sleeve to the fluid and prevent the protective sleeve from breaking under the action of the fluid. The protection tube shallow insertion method or hot sleeve thermal resistance can be used. The depth of the shallow plug-in thermal resistance protective sleeve inserted into the main steam pipe shall not be less than 75mm. The standard insertion depth of thermal resistor is 100mm; C. If it is necessary to measure the flue gas temperature in the flue. Although the flue diameter is 4m, the thermal resistance insertion depth is 1m; D. When the original insertion depth exceeds 1m, it shall be installed vertically as far as possible. Or add support frame and protective sleeve. |