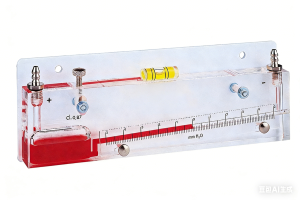

TX 50 Inclined Liquid Column Manometers

5-0-5 mm H2O or 50-0-50 Pa

Measurement range: Measurable pressure range (e.g. 0-25 Pa, 0-100 mmH ₂ O, etc.).

Tilt angle: usually provides fixed or adjustable angles (such as 15 °, 30 °, 60 °, etc.), the smaller the angle, the greater the amplification factor for small pressures, and the higher the sensitivity.

Structural materials: base, measuring tube, and liquid type.

| Recommended range of use | From +5 to +30 °C |

| Possible range of use | From -30 to +60 °C |

| Maximum static pressure | 6 bars |

| Manometer body | Transparent 15 mm thick Altuglas |

| Liquid column | Entirely bored in the solid block, Ø 4 mm |

| Graduated slide strip | Transparent Altuglas. Cross-section 20 x 2 mm |

| Zero adjustment | By moving the graduated slide strip, travel 20 mm. Fixed via milled, nickel-plated brass screw |

| Positionning | Horizontal positioning via integrated spirit level and milled, nickel-plated brass adjusting screw, vertical travel 12 mm |

| Manometric liquid | AWS 10 red oil, density 0.87 at 15 °C |

| Reservoir capacity | 20ml |

| Connection | Ø 5 x 8 mm semi-rigid crystal tube, on Ø 6.2 mm ribbed, nickel-plated brass connectors, 1/8 gas thread |

| Wall-mounted | With or without white PVC support |

Advantages:

High sensitivity: Very suitable for extremely low pressure measurements.

Simple structure, high stability and reliability.

Price: Economical and cost-effective

Portable and easy to read: Integrated design, no need for power supply, can be carried to the site for direct reading.

Application:

Heating, Ventilation, and Air Conditioning (HVAC): Accurately balance duct systems, measure supply/return air pressure differentials, filter resistance, and room positive/negative pressure.

Cleanrooms and laboratories: monitoring and controlling micro pressure differentials that are crucial for the environment.

Industrial ventilation and environmental protection: measuring the pressure of small airflow in flues and pipelines.

Equipment maintenance and debugging: used for calibrating or inspecting pressure sensors in building automation systems.

Work precautions:

Leveling is the top priority: before use, be sure to adjust the base to ensure that the yellow level bubble is strictly centered.

Slow connection: When connecting the pressure measuring tube, the knob should be slowly opened to avoid sudden pressure changes that may impact the liquid column.

Keep clean: prevent the measuring tube from being contaminated or blocked.

Liquid replenishment: If the liquid evaporates or is missing, it needs to be replenished by professionals using a designated working fluid with a specific gravity of 0.87, otherwise it will introduce measurement errors.

FAQ:

Q1,How to read measurement values correctly?

A: Leveling: Ensure that the yellow horizontal bubble is centered.

Zero adjustment: In the absence of pressure difference, use the blue knob to adjust the liquid level to the “0” position.

Connection: Connect the pressure source correctly to the “+” and “-” interfaces.

Reading: After the liquid column stabilizes, read the scale value corresponding to the red liquid column meniscus (usually the lower edge). The unit is mm H ₂ O (millimeter water column). For example, if the liquid column moves 3 grids from position 0 to the “-” side, the reading is -3 mm H ₂ O, indicating that the pressure at the “-” end is 3 mm H ₂ O higher than that at the “+” end.

Q2: What is the purpose of the yellow horizontal bubble at the top?

This is a horizontal indicator. Due to the measurement principle of the instrument relying on gravity, it is necessary to ensure that the instrument is completely level during use, otherwise measurement errors may occur. Before use, it is necessary to adjust the foot at the bottom of the instrument to ensure that the yellow bubble is located within the central ring.

Q3:What does the measurement unit mm H ₂ O mean? How to convert?

A:Millimeter water column (mm H ₂ O): is a commonly used unit in the low-pressure field, representing the pressure generated by a water column 1 millimeter high under standard gravity.

Common Conversion:

1 mm H ₂ O ≈ 9.8 Pa (Pascal)

10 mm H ₂ O ≈ 1 daPa (Ten Pascal)

1000 mm H ₂ O=1 m H ₂ O (meter water column)

Q4:What are the precautions for use and storage in maintenance and precautions?

A:Handle with care: Avoid severe vibrations or impacts to prevent damage to fragile acrylic pipes and internal structures.

Keep clean: prevent blockages in interfaces and pipelines.

Avoid extreme temperatures: temperatures that are too high or too low can affect the density of the working fluid and the accuracy of the instrument.

Keep the interface facing upwards during transportation, preferably with the knob closed.

Q5:What should I do if I find that the red oil liquid is missing, there are bubbles, or the reading is inaccurate?

A:It is strictly prohibited to add ordinary liquids or water by oneself. This will result in a change in density and a complete misalignment of the instrument.

If the liquid is missing, large bubbles are generated, or the instrument is suspected to be inaccurate due to impact, it should be stopped from use and professional technical support should be contacted or sent back to qualified institutions for repair, refilling, and calibration.

For more information on the range and pressure of using Inlined Liquid Column Manometers in different industries such as HAVC, please refer to this article:https://www.derkia.com/how-to-choose-inclined-liquid-column-manometers%ef%bc%9f/