Classification by Application Scenario and Characteristics

1. Seismic-resistant pressure gauge

This is the most widely used pressure gauge in oil fields, almost ubiquitous.

Core Features: The case is filled with damping fluids such as glycerin or silicone oil, equipped with a rubber diaphragm or piston-type membrane, which effectively buffers pulses and severe vibrations, prevents pointer jitter, extends service life, and facilitates reading.

Application Scenario:

Drill pumps, mud pumps: Measure the pressure of the drilling fluid, with significant fluctuations in pressure and flow rate.

Compressor and plunger pump outlet: Intense pressure pulses.

Wellhead equipment: Resists vibrations during drilling and production operations.

2. High-temperature pressure gauge

Core Features: – Utilizes high-temperature-resistant core materials (such as stainless steel) and special sealing materials. – Designed with a heat dissipation structure to prevent direct transfer of high temperatures from the medium to the elastic components.

Application scenarios:

Steam Injection Equipment (for Heavy Oil Recovery).

Hot media furnace and boiler system.

Near the reactors and heating furnaces of the refining unit.

3. Corrosion-resistant pressure gauge

Low pressure range: 0~0.1 MPa to 0~2.5 MPa (similar to full plastic type).

Medium and high pressure range: 0~4.0 MPa to 0~60 MPa or even higher.

Core Features: The contact liquid components (such as connectors and Bourdon tubes) are made of stainless steel (e.g., 316, 316L) or coated with anti-corrosion materials (e.g., Hastelloy, Monel alloy, tantalum). For highly corrosive media (e.g., hydrogen sulfide, acidic gases), sulfur-resistant pressure gauges must be used.

Application scenarios:

Sulfur-containing acidic oil and gas fields: Mandatory use of sulfur-resistant materials to prevent sulfide stress corrosion cracking.

Chemical process, seawater injection system.

Measurement separator: Contact with multiphase mixtures such as oil, gas, water, and sand.

4. Diaphragm pressure gauge

Core Features: The measurement medium is isolated from the pressure gauge mechanism via a diaphragm isolation device. The diaphragm material can be selected based on the corrosiveness of the medium (e.g., Hastelloy, tantalum, PTFE lining, etc.). It is particularly suitable for highly viscous, easily solidifying, crystallizing, or extremely corrosive media.

Application scenarios:

Measurement of heavy oil, asphalt, slurry, chemical agents, and the like.

Food-grade and hygienic requirements (e.g., oilfield additive injection systems).

5. Electric contact pressure gauge

Core Features:

The device is equipped with an electrical contact mechanism on the basis of a pressure gauge. When the pressure reaches the preset upper or lower limit, it connects or disconnects the control circuit, enabling automatic alarm or interlock control.

Application scenario:

Automatic start-stop control of the compressor.

Pressure and pressure vessel overpressure alarms and safety interlocks.

Dry run protection for the pump.

6. High-precision pressure gauge/standard pressure gauge

Core Features: High accuracy class (e.g., Class 0.4, Class 0.25), suitable for calibrating standard working pressure gauges or conducting precision measurements.

Application scenarios:

Calibration tools for on-site instrument technicians in oilfields.

Key points requiring precise measurement and accounting.

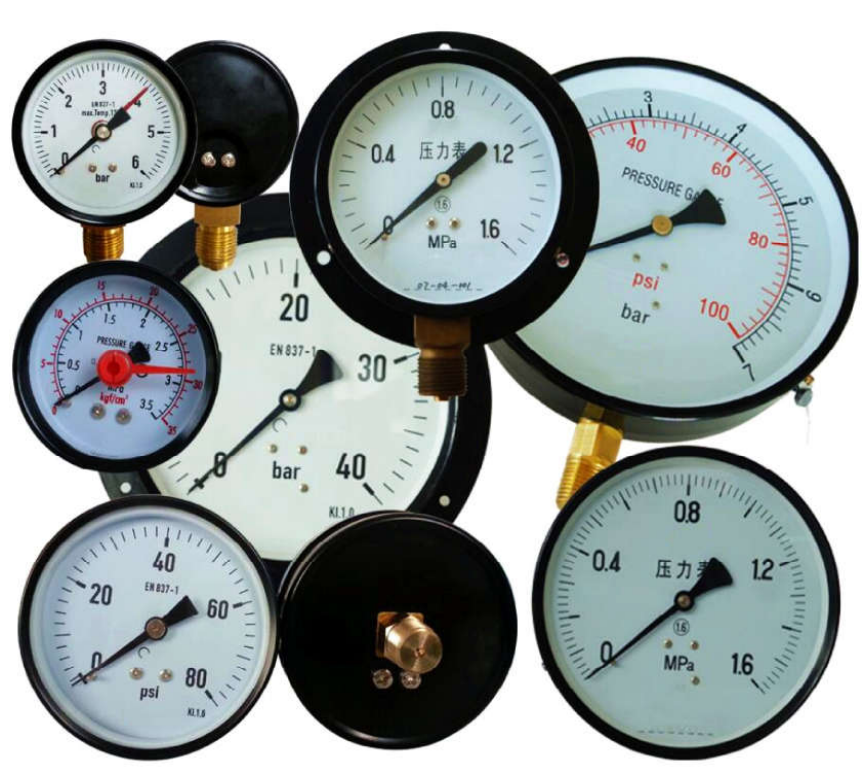

How To Order?

Gauge type:

Y-General pressure gauge

YTN-Liquid fillable pressure gauge

Y-General pressure gauge

YTN-Liquid fillable pressure gauge

YBF-All stainless steel pressure gauge

YTU- Sulfur Resistant pressure gauge

YA- Ammonia pressure gauge

YB-Precision pressure gauge

YC- Marine pressure gauge

YD- Absolute pressure gauge

YE- Capsule low pressure gauge

YF- Diaphragm pressure gauge

YO- Medical gauge

Mounting:

A – Radial

D-axis

BD- axial band edge

LBM- Eccentric Axial

U-clamp protective bracket

Diameter: 40-φ1 1/2“/50-φ2”/60-φ2 1/2”/75-φ3”/80-φ3 1/2”/100-φ4”/115-φ4 1/2”/150-φ6”/200-φ8”

Oil filled/Dry: 1.G-Glycerin / 2.S-Silicone oil / 3.Dry