HVAC Instruments

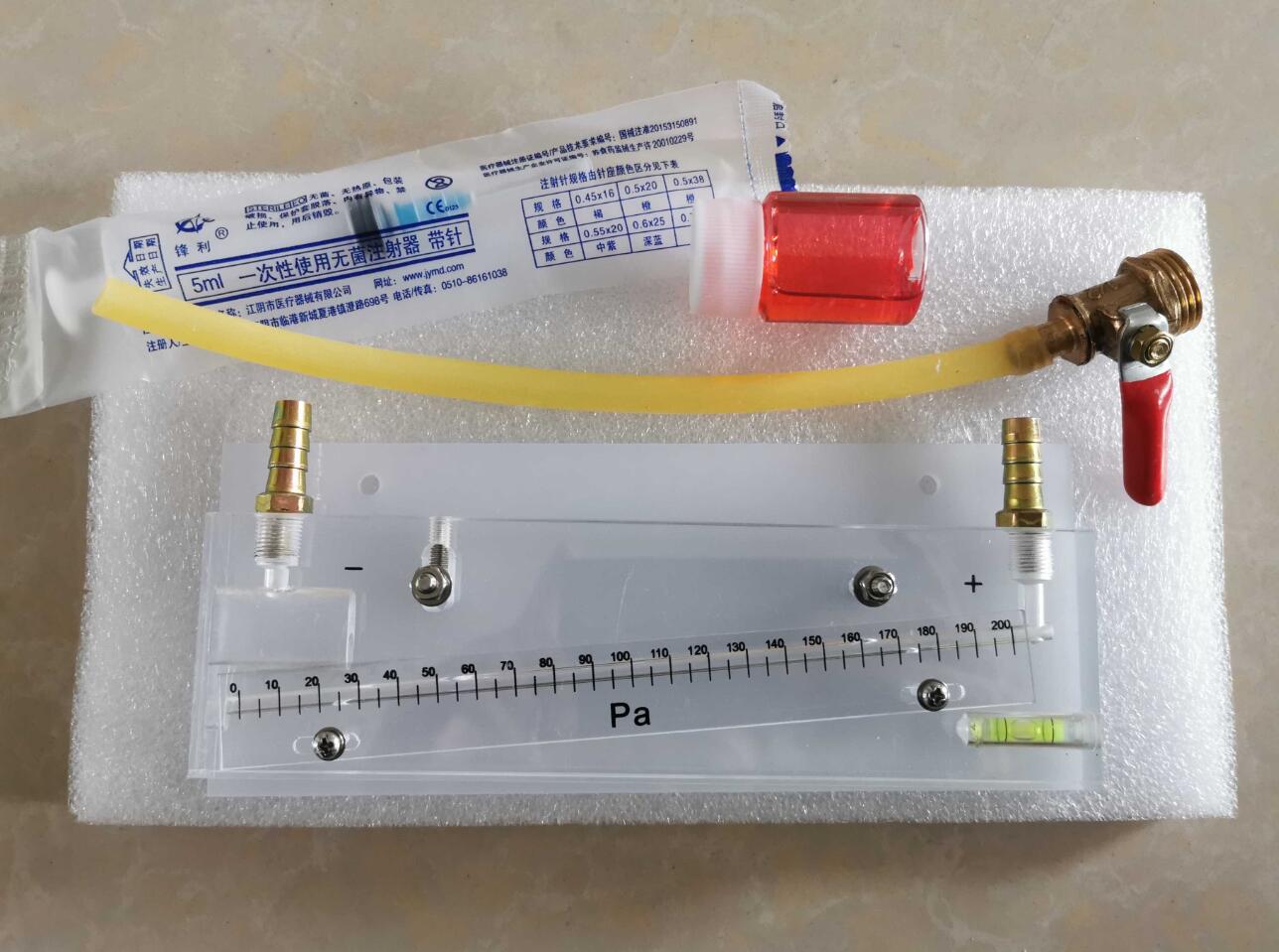

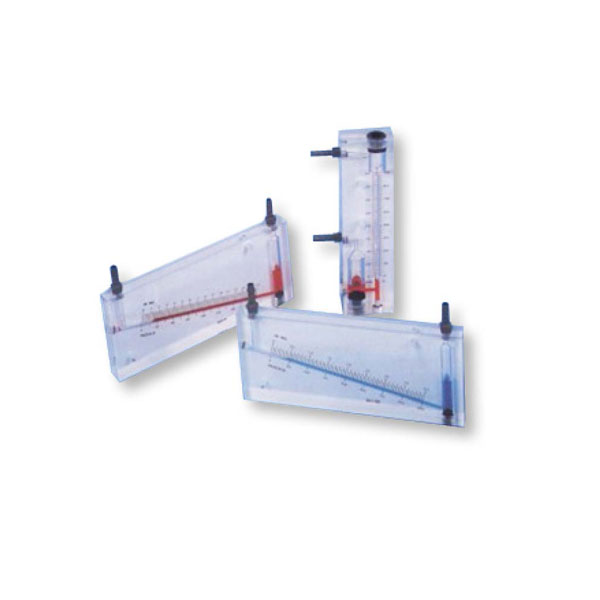

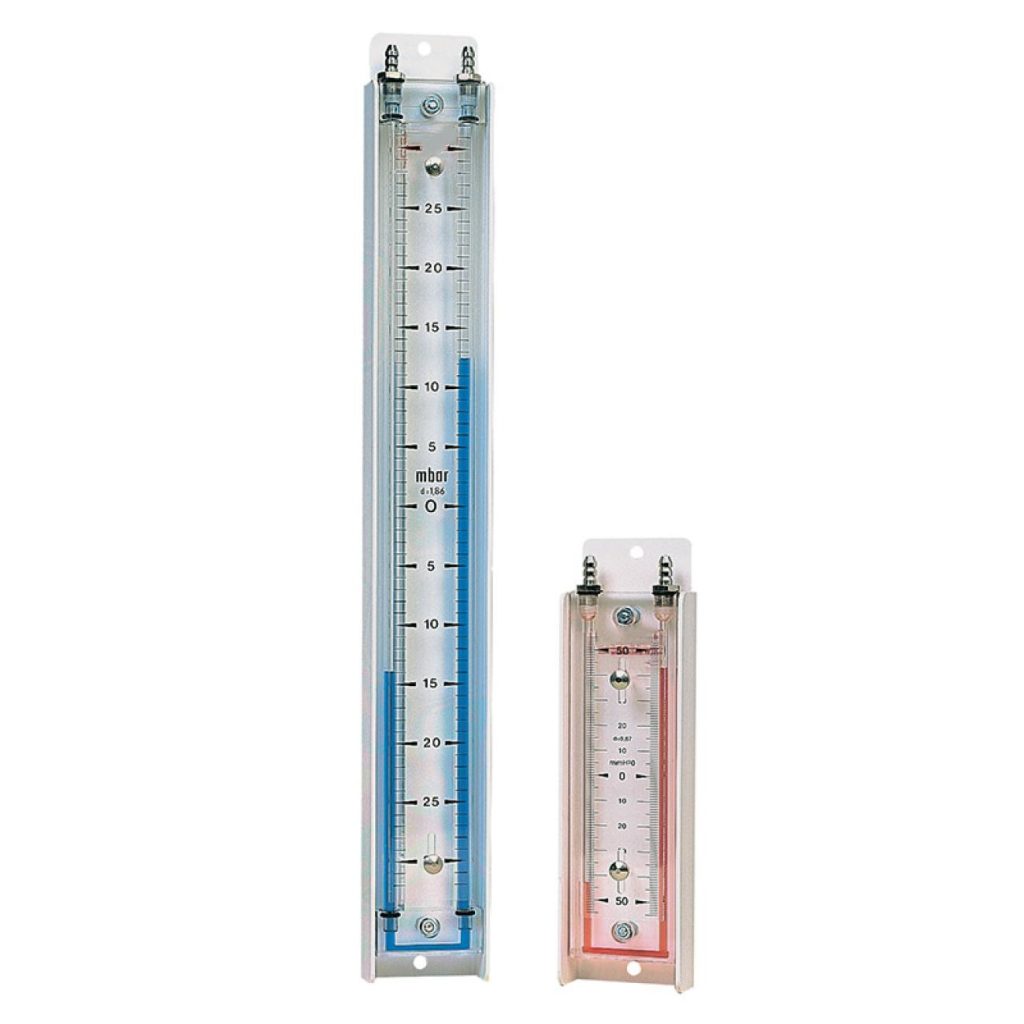

Differential pressure gauge

The most common and widely used application area for HVAC differential pressure gauges. Mainly used to monitor the flow resistance of air or liquid to ensure efficient system operation and provide maintenance warnings.

Filter status monitoring:

Air filter: installed before and after the primary and medium filters of the air conditioning unit or fresh air unit. As the filter gradually becomes clogged, the pressure difference before and after it will increase. The reading on the differential pressure gauge can visually indicate whether the filter needs to be cleaned or replaced. This is the most classic application.

Water filter: Monitor whether the Y-shaped filter on the pipeline of the chilled water and cooling water system is clogged.

Fan/duct performance monitoring:

Monitor the pressure difference between the inlet and outlet of the fan to determine if the fan is working properly.

Monitor the pressure situation of the air duct in the variable air volume system.

Cleanroom pressure monitoring:

In clean rooms such as biological laboratories, pharmaceutical factories, and electronic workshops, it is necessary to maintain positive indoor pressure (to prevent external contaminated air from entering) or negative pressure (to prevent harmful substances from escaping from the interior). Acrylic differential pressure gauges are widely used to measure the slight pressure difference between indoor and outdoor or different levels of clean areas.

Pressure range:

0-50Pa/0-100Pa/0-200Pa/0-400Pa/0-500Pa/0-600Pa/0-800Pa/0-1000Pa

-2.5-2.5 mmH₂O/ -5-0-5 mmH₂O/ -7.5-0-7.5 mmH₂O/ -10-0-10 mmH₂O/ -20-0-20 mmH₂O/ -25-0-25 mmH₂O/ -30-0-30 mmH₂O/ -40-0-40 mmH₂O/ -50-0-50 mmH₂O

-25Pa-0-25Pa/ -50Pa-0-50Pa/ -75-0-75Pa/ -100-0-100Pa/ -200-0-200Pa/ -250-0-250Pa/ -300-0-300Pa/ -400-0-400Pa/ -500-0-500Pa

Air Differential Pressure Switch

| Model | Air Differential Pressure Switch |

| Medium Air | non-combustible and non-aggressive gasses |

| Max Pressure | 10 kPa |

| Mounting position | Diaphragm in any vertical plane |

| Protection degree | IP54/IP65 (with cover) |

| Temperature | 40° C to 85° C |

| Contact | SPDT |

| Electrical Rating | 1.5A (0.4A) / 250V |

| Terminals | 6.3 mm(0.25″) copper alloy |

| Connection | 6.0mm Dia |

| Approval | CE/ISO9001 |

| Model | Pressure Rang | Differential | Toleranc |

| Pa | 20 ~ 200 Pa | 10 Pa | ±15% |

| Pa | 30 ~ 300 Pa | 10 Pa | ±15% |

| Pa | 40 ~ 400 Pa | 20 Pa | ±15% |

| Pa | 50 ~ 500 Pa | 20 Pa | ±15% |

| Pa | 200 ~ 1000 Pa | 100 Pa | ±15% |

| Pa | 500 ~ 2500 Pa | 150 Pa | ±15% |