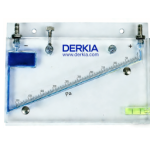

MG 50 Inclined Liquid Column Manometers MG models.

Measurement pressure range of inclined micro differential pressure gauge: 0 Pa to 500 Pa (pascal).

Specification:

Measurement range: 0-500 Pa. This is its main scale range, used for precise measurement of small pressure differentials.

Joint: Two metal joints, one set is “+” (positive pressure end) and the other set is “-” (negative pressure end). Used for convenient connection of hoses with different diameters.

Working temperature: 0 ° C to 40 ° C, avoid extreme temperature affecting liquid properties and accuracy.

Balance attachment: The instrument integrates a level to ensure that the instrument is in a standard horizontal position during measurement, which is a prerequisite for accurate readings.

How to install and use the instrument?

1. Placement and leveling: Place the instrument steadily on a desktop or stand. The crucial step is to observe the built-in level and adjust the footrest at the bottom of the instrument until the bubble is centered, ensuring that the instrument is completely level.

2. Connecting pipelines:

Connect one end of the hose to the connector marked with a “+” on the instrument panel, and the other end to the high-pressure side (positive pressure point) to be tested.

Connect one end of the other hose to the “-” connector and the other end to the low-pressure side (negative pressure point).

Ensure that the hose connection is tight and free of gas leaks.

3. Read the pressure difference:

After connecting the hose, the blue liquid column inside the U-shaped tube will move due to pressure difference.

Method for reading pressure values: Observe the position of the left liquid level on the main scale. Due to its inclined design, the scale directly corresponds to the Pascal value. The scale value of the liquid level indicator is the current pressure difference value (Δ P).

If the liquid surface moves in the “+” direction, the reading is a positive pressure difference; Otherwise, it is the negative pressure difference.

4. Range switching (if need): If you need to measure pressures greater than 500Pa, you may need to adjust the zero position setting on the instrument to use a higher scale range. Please refer to the instructions for the specific model for operation.

Application:

This instrument is designed specifically for measuring extremely low pressures, pressure differentials, or wind speeds (converted through pitot tubes) and is commonly used for:

1. HVAC system: Measure the pressure difference before and after the filter, fan static pressure, duct pressure, room positive and negative pressure, etc.

2. Cleanroom monitoring: Monitor the pressure difference between the room and the corridor.

3. Industrial ventilation and environmental protection: detect small pressure differences in dust removal equipment and combustion equipment.

4. Laboratory: used for physical experiments or equipment debugging that require measurement of low voltage difference.

Important precautions during use:

1. Level is key: any lack of level can lead to significant reading errors.

2. Liquid medium: The blue liquid inside the instrument is usually a specialized dye colored alcohol or oil-based solution, with a stable and unchanged density. Do not replace or mix with other liquids at will.

3. Avoid overpressure: When opening the valve of the tested system, please open slowly to avoid severe pressure impact that may cause liquid to rush out of the tube.

4. Cleaning and maintenance: Disconnect the hose after use to prevent dust from entering the joint. Keep the instrument clean and avoid damaging the transparent panel and scale.

5. Environmental temperature: Try to use at room temperature as extreme temperatures can affect liquid density and reading accuracy.

FAQ:

Q1: What kind of instrument is this? What is it mainly used to measure?

A: This is a tilted micro differential pressure gauge, which belongs to a type of liquid pressure gauge. It is specifically designed for precise measurement of small pressure differences between two points of gas or liquid, with a core measurement range of 0 to 500 pascals (Pa).

Q2: How to connect pipelines correctly?

A: The instrument is marked with “+” and “-” on both sides.

(1) +”interface (high pressure end): Connect to sources with high pressure or requiring measurement of positive pressure.

(2) – “Interface (low pressure end): Connect to a source of lower pressure or as a reference pressure.

Q3: How to correctly read the pressure value?

A:Firstly, ensure the instrument is level: use the built-in level in the bottom right corner of the instrument for leveling, which is the key to accurate readings.

Direct reading: Observe the meniscus of the blue liquid column on the left side of the U-shaped tube and the corresponding scale value on the tilted white scale band. This value is the current pressure difference (unit: Pa).

Q4: How to zero the instrument?

A: After ensuring the level of the instrument, connect the “+” and “-” interfaces to the atmosphere (or to each other), and the pressure difference should be zero. If the liquid level is not aligned with the 0 mark, you can carefully rotate the zero adjustment knob on the instrument (usually located at the bottom or side) until the liquid level accurately points to 0 Pa.

Q5: What if the blue liquid inside decreases or leaks?

A: Do not add regular liquids by yourself. The blue liquid inside the instrument is a specialized oil-based or alcohol solution with a specific density, which directly affects the accuracy of the scale. If occur leak or evaporation resulting in insufficient liquid volume, contact DERKIA official for new measuring oil.

Q6: Can I measure negative pressure (vacuum)?

A: Okay. This instrument measures differential pressure. When you connect a negative pressure source (such as an exhaust duct) to the “+” port and open the “-” port to the atmosphere, the instrument will display the negative pressure value relative to atmospheric pressure. When reading, the liquid column will rise towards the “-” side (low pressure side). What you need to read is the absolute value of the scale value corresponding to the left liquid level, but understand it as a negative pressure state.

Q7: What should I do if the liquid column jumps unstably during measurement?

A: Unstable liquid column usually indicates pulsation or turbulence in the measured pressure source itself. You can:

Install a small volume stabilizing tank or “pulsation damper” (such as an expansion chamber with small holes) on the measuring pipeline.

Check if all connections are completely sealed and if there is any air leakage.

Ensure that the hose is not bent or severely bent.

Q8: How to clean the instrument safely if it is dirty?

A: Disconnect all connections in work.

Please use a soft, slightly damp cloth to wipe the instrument casing and transparent cover.

Absolutely avoid using organic solvents, strong acid and alkali cleaners, or abrasive materials to prevent corrosion of the casing or scratching of the scale cover.

Do not allow liquid to flow into the interface or inside the instrument.

Q9: What should be noted when using outdoors or in environments with vibration?

A: This instrument is highly sensitive to levels and stability.

1. Outdoor workplace: Use sturdy supports and check the level at all times, as wind or uneven ground may cause tilting.

2. Vibration environment: Vibration can cause severe shaking of the liquid level, making it impossible to read. The instrument should be installed on a stable foundation as far away from the seismic source as possible, or shock-absorbing pads should be used.

Q10: What should I do if the instrument accidentally falls or if there are bubbles/fractures in the liquid column?

A: Stop using immediately. The appearance of bubbles or disconnection in the liquid column indicates that the instrument is no longer sealed or the working fluid is contaminated/lost, and the reading will be completely invalid. At this time, users cannot handle it themselves. Please contact the official website www.derkia.comhttp://www.derkia.com to find service support.