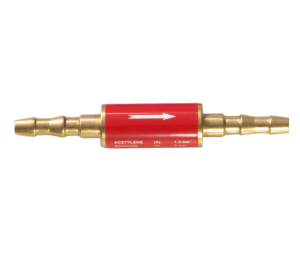

The FRB series is a modular anti backfire safety device designed specifically for industrial gas cutting and heating systems, providing dedicated models for acetylene and propane core gases. This series of products is directly installed at the low-pressure outlet end of the corresponding gas pressure regulator, serving as a “safety sentinel” in the gas circuit. Through its millisecond level response thermal cut-off mechanism, it instantly physically blocks the flame backpropagation path in the event of backfire, providing the highest level of intrinsic safety protection for core gas supply equipment (regulators, gas cylinders/busbars) and operators. The serialized design ensures optimal matching for different gas characteristics and is a standard configuration for achieving safe and efficient gas operations.

Parameter comparison:

| FRB-A10 (acetylene specific type) | FRB-P40 (propane specific type) | Design and Safety Instructions | |

| Applicable gases | (C₂H₂)Dissolve acetylene (C ₂ H ₂) | (C₃H₈ / LPG)Propane/Liquefied Petroleum Gas (C ∝ H ₈/LPG) | Specially designed based on gas chemical characteristics and combustion rate, mixing or replacement is strictly prohibited. |

| Max work pressure | 1.5 bar | 5 bar | Accurately match the standard outlet pressure of each pressure reducer. Propane has a higher working pressure, so the valve pressure and sealing design are different. |

| Rated flow rate | 10 m³/h | 40 m³/h | Propane has a lower calorific value and usually requires a much larger volumetric flow rate than acetylene, so the P40 model has a greater flow capacity. |

|

Entrance/exit connection |

6mm or 8mm hose connector |

6mm or 8mm hose connector |

Difference: Acetylene type inlet has left-hand threads (reverse threads), while propane type has conventional right-hand threads. This physical distinction is the core safety design to prevent misconnection. Optimize the tempering characteristics and airflow temperature for different gases. |

| Trigger temperature | 95 ± 10 ° C | 105 ± 10 ° C | Optimize the tempering characteristics and airflow temperature for different gases. |

| Valve body color identification | red or labeled with “acetylene” | blue or labeled with “propane/LPG” | Provide visual differentiation, strengthen on-site gas management, and prevent misuse. |

| Core safety standards | Compliant with EN ISO 5175-1 (acetylene) | Compliant with EN ISO 5175-2 (propane/LPG) | Follow international safety regulations for different gases separately. |

Common features of series products:

Exclusive optimization of gas characteristics:

The internal flow channels, spring tension, and thermal sensors are calibrated for specific gas pressure, flow rate, and combustion characteristics to ensure minimal pressure loss during normal operation and extremely fast response in dangerous situations.

Double protection security mechanism:

Main safety valve: Hot melt or thermal expansion mechanical shut-off valve, which operates instantly in the event of high temperature and permanently/temporarily closes the main air circuit.

Auxiliary check valve: Integrated precision check valve to prevent gas backflow and pressure fluctuations, providing dual protection.

Intelligent status indication and convenient maintenance:

All are equipped with intuitive mechanical status indicator windows (such as green “safety”/red “trigger”), which can be quickly identified without tools.

Adopting replaceable safety core modules. After triggering, only the internal core needs to be replaced, and the valve body can be reused, greatly reducing maintenance costs and downtime.

Application:

FRB-A10 (acetylene type): All gas welding, gas cutting, and flame cleaning operations using dissolved acetylene.

FRB-P40 (propane type): flame cutting, metal preheating, brazing, asphalt heating, ceramic firing and other processes using propane as fuel.

Dual fuel workstation: a system that uses acetylene and propane simultaneously in the same workspace, providing targeted protection for each gas path.

Order Information

Acetylene specific models: FRB-A10-F06 (export 6mm)/FRB-A10-F08 (export 8mm)

Propane specific models: FRB-P40-F06 (export 6mm)/FRB-P40-F08 (export 8mm)

spare parts

Acetylene safety core module (Cartridge-A)

Propane safety core module (Cartridge-P)